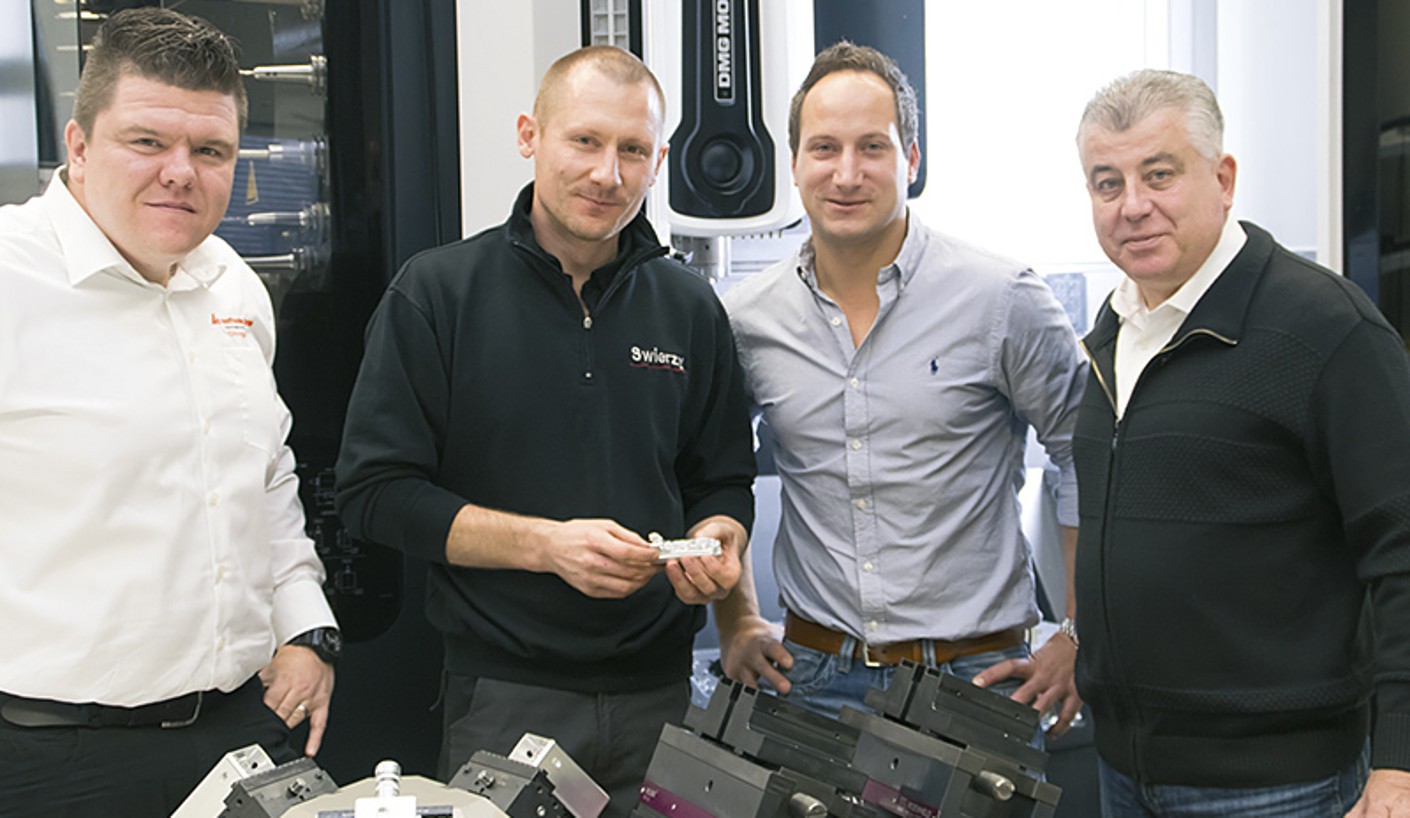

"Highly flexible clamping technology which is ideally suited to our 5-axis machine!"

WITHIN A VERY SHORT TIME, A REDUCTION OF NON-PRODUCTIVE TIMES AND A SIGNIFICANT INCREASE OF THE SPINDLE RUNTIME WERE BECOMING APPARENT.

The core business of Swierzy CNC Produktionstechnik is contract manufacturing of high-quality milled components of varying complexity – from individual parts right up to large series. Amongst their customers are companies form various sectors such as mechanical engineering, medical technology, the automotive industry and the food industry. A bicyle manufacturer and a watch manufacturer are also amongst their customers. In November 2015 the company moved to newly built premises, and in September 2016 they acquired their first 5-axis machining centre.

We were looking for a highly flexible clamping system, which would be ideally suited to our 5-axis machine and our components. It needed to be precise, versatile in its applications and, moreover, easy to use. We also wanted it to reduce set-up times.

Right from the outset, the Hoffmann Group was a much appreciated and reliable partner who visited us on a regular basis, looked after us and introduced the GARANT ZeroClamp system early on – at a point in time when we hadn't even recognised the need for it. The application engineers of the Hoffmann Group showed us the efficiency and the simplicity of the system.

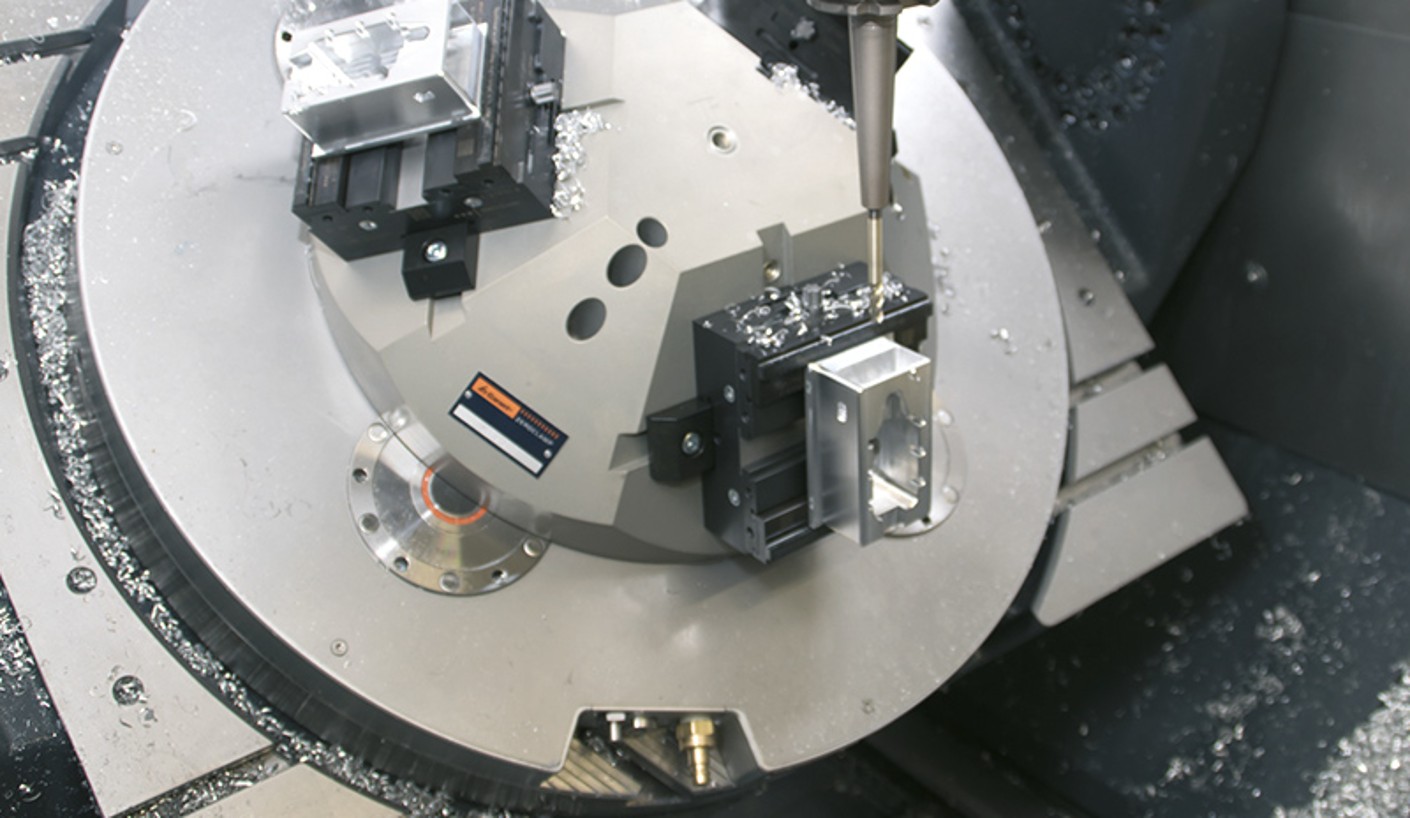

We have been working with the zero point clamping system since the commissioning of our new 5-axis machining centre in September 2016. As GARANT ZeroClamp is the base on the machine, the system is being used for any work and material.

We use GARANT ZeroClamp several times per day. Whether for direct clamping, as a base for vices, centring vices or 3-way extension bases. Our employees think and live GARANT ZeroClamp and don't want to use any other clamping system.

The simple and efficient design with just a minimum of mechanics, the easy handling e.g. by using just one type of stud and also the fact that thermal symmetry is assured, were the decisive factors influencing our decision. Another factor that convinced us was the wide range and consistent range of available accessories.

The reduction of non-productive times and thus a significant increase in spindle running time was notice-able after just a short time. Another advantage that we benefit from on a daily basis is the opportunity to act more flexibly as the zero points can be replicated.

We have the basis for the GARANT ZeroClamp system, which will now be expanded and installed on more machines. For us, GARANT ZeroClamp is the best system on the market.

Swierzy CNC-Produktionstechnik was founded in 2010 by Benjamin Swierzy, and since then has been synonymous with individual, precisely executed customer solutions, on-time deliveries and highquality milling. Their portfolio includes a variety of made-to-order milled parts – ranging from prototypes and individual parts right through to large series. The products are made to the customers' exact requirements.

The company operates mainly regionally in East Westphalia and in the adjoining Lower Saxony, but also throughout the rest of Germany and worldwide, for example in Iceland and Sweden.

Apart from mechanical processing, Swierzy CNC-Produktionstechnik together with its production partners also offers its customers various options for further processing. The tried and tested regional supplier network makes prompt execution of all orders possible. In 2016, the qualified staff of eight achieved an annual turnover of 1.2 million euros.