50 % fewer tools kept at machines

At Röhm the new Tool Managmenet System has established lean processes, reduced tool stocks and improved the security of supply.

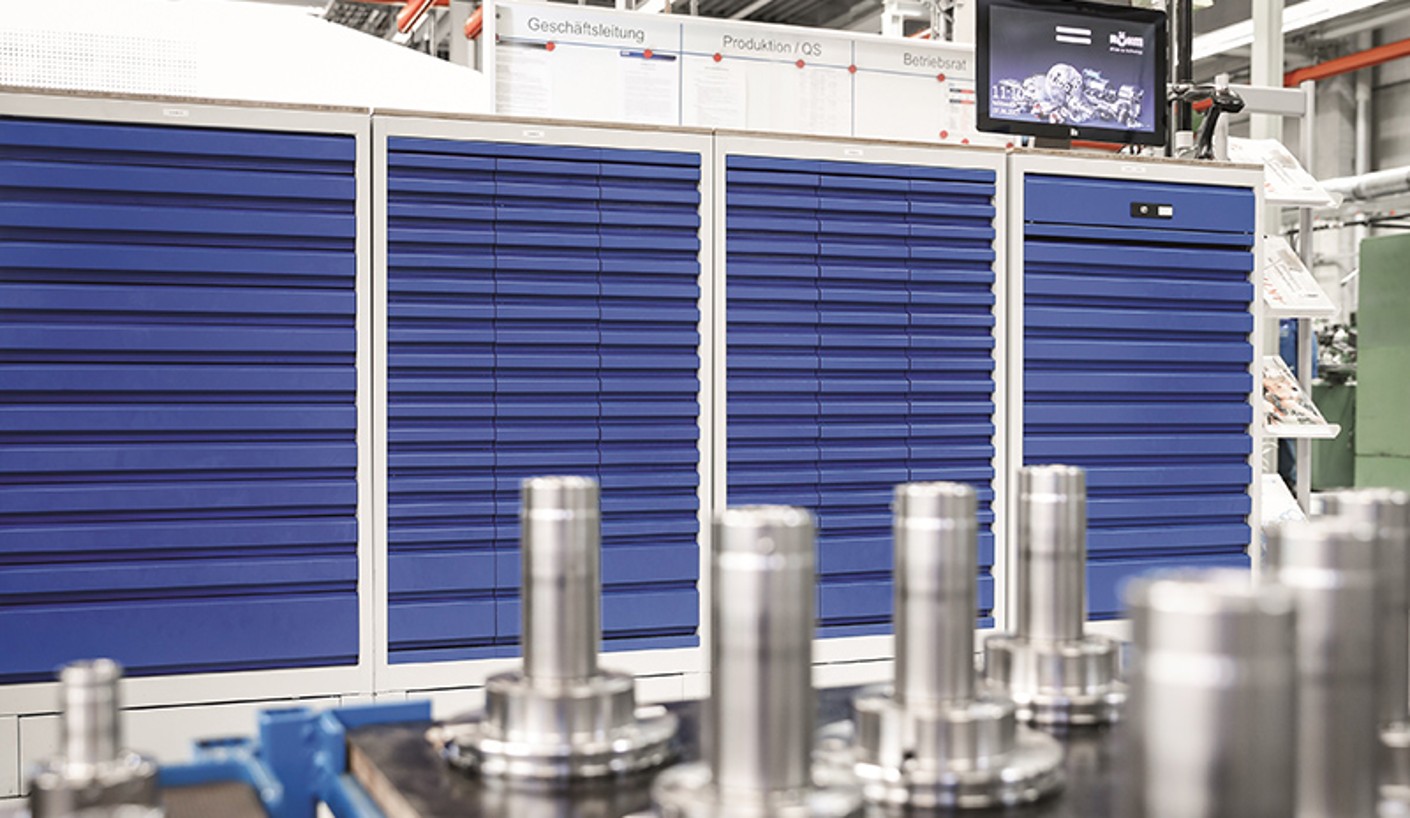

Röhm, a traditional company in Sontheim on the Brenz, Germany, can look back on a long and successful history. Founded in the year 1909, today Röhm is one of leading manufacturers of clamping equipment in the world. Throughout its eventful history, the company Röhm has continually responded to new market challenges and modernised its production processes. An example of this was the decision to automate the issuing of indexable inserts and abrasive media by introducing the GARANT Tool24 Smartline goods issuing system from the Hoffmann Group.

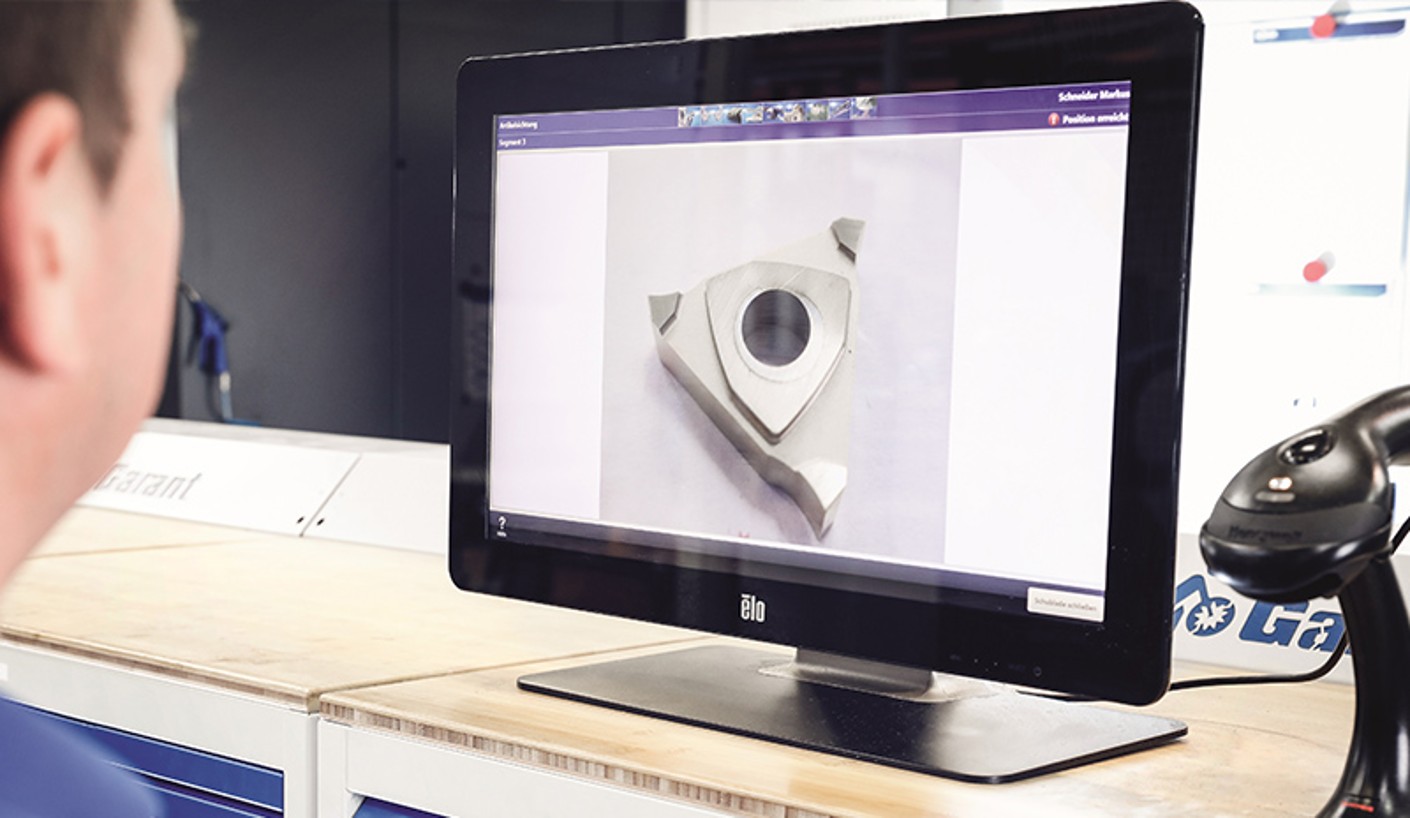

Markus Schneider, Foreman (left) and Fabian Baur, Product Manager (right)

Security of supply at the machine required

The example of chucking tool manufacturer Röhm, based in Sontheim Germany, illustrates how a company can benefit from the introduction of a Tool Management System. In 2014, Röhm automated its tool issuing process for indexable inserts and grinding media by introducing the Tool Management System GARANT Tool24 Smartline. Before the introduction of GARANT Tool24 Smartline, Röhm used the classic technique for issuing tools. The two tool issuing points were only open at specific times. There was therefore a continuous threat of bottlenecks. Assuring supply for the early shift at the start of the week proved to be especially problematic, which is why Röhm decided to introduce a tool issuing system.

The search for flexibility

Fabian Baur, Product Manager at Röhm, summarised the requirements as: “We wanted a system that we could adapt individually to our ideas and be able to extend as required”. “In addition, the system should be able to operate round the clock without problems and offer various drawer sizes.”

Reliable requirements planning thanks to the link to SAP

It was also important for Röhm that the system delivered a standard interface to SAP so that stock withdrawals, stock receipts and corrections were always clearly recorded and could, if necessary, be precisely scheduled.

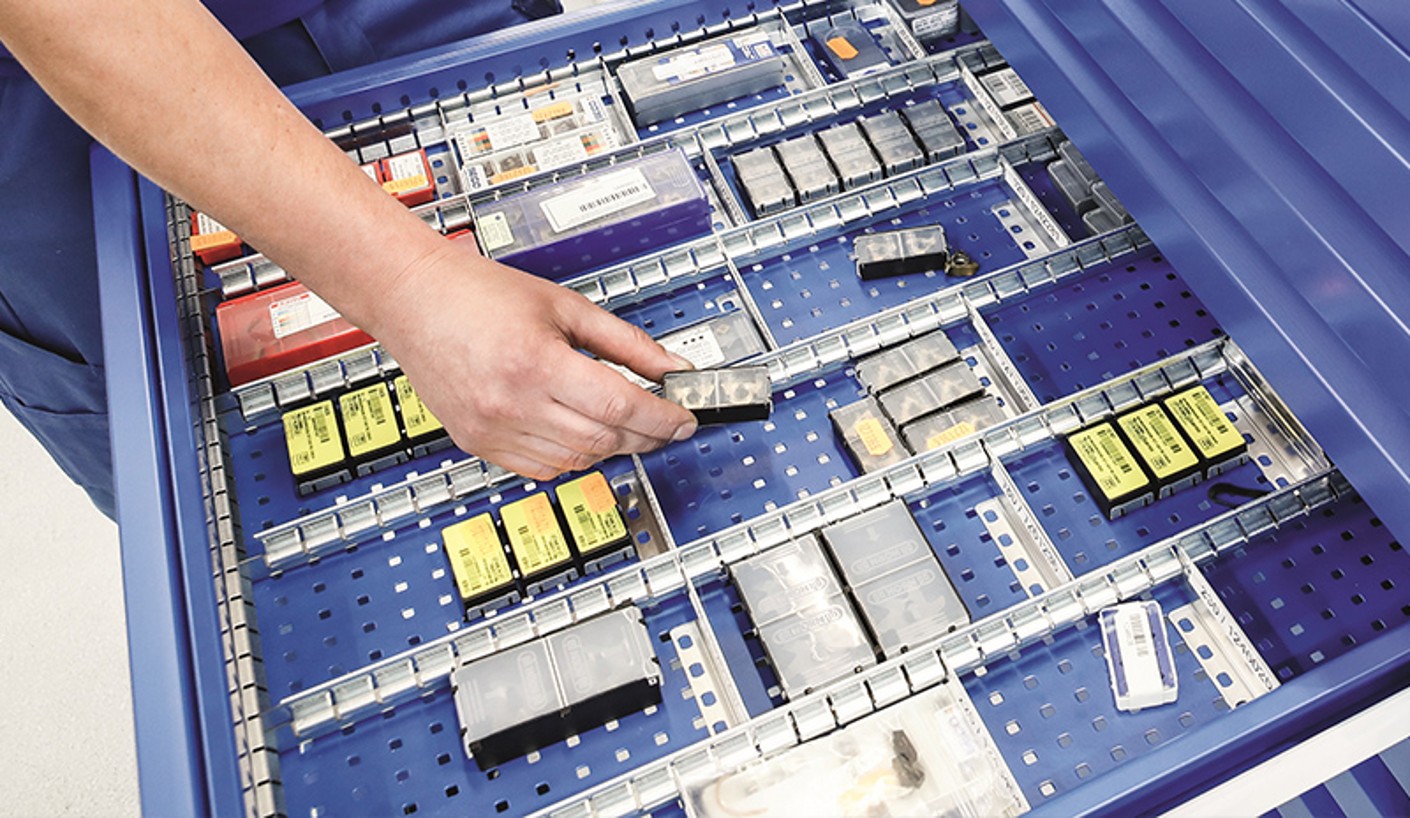

750 articles stored

In the meantime Röhm is now storing 750 articles from different suppliers in the GARANT Tool24 Smartline. Once the employee has logged into the system by scanning his identification card, he can also see the standard designation and the product price alongside the product image and product name. "Because they see the prices, employees handle tools with greater awareness", Markus Schneider, Foreman in Segment 5, Projects, at Röhm has noticed. "They now specifically choose the cheaper tool for a certain process, and the tools are used for longer."

Getting a tool is now 3 times faster than before

Nowadays, the distances covered have reduced considerably as the GARANT Tool24 Smartline is placed at a central location on the factory floor, easily accessible for everyone. Even though the employees go to the tool issuing system more frequently to get new material, efficiency within the company has increased significantly, because obtaining a tool is now approx. 3 times faster than before

50 percent reduction in stocks kept at the machines

Since the introduction of Tool24 Smartline the need at Röhm to keep indexable inserts and abrasive media at the workplace has reduced by half.

Because Tool24 Smartline is so convenient, Röhm is considering using it for storage of taps and similar tools. "It is good to know that we can simply extend the system if necessary" explains Schneider. And Baur concludes: "GARANT Tool24 Smartline has convinced us and we would recommend it without any hesitation."