Increased profitability with the right tooling concept

Special-purpose machine manufacturer Glatt reduces cycle times by 90% and production costs by 70%

The special-purpose machine manufacturer Glatt Systemtechnik GmbH is a market leader in life science systems for the refinement and processing of powders. With 14 branches and subsidiaries worldwide, Glatt supports customers in pharmaceuticals, food and feed processing and fine chemicals through their innovative process solutions. At the Dresden location Glatt produces individual product handling systems. This means that each machine is individually manufactured to customer order.

In comparative tests, Glatt Systemtechnik GmbH thoroughly tested several machine tools at its Dresden site, with astonishing results.

Extensive machine tool tests

When it comes to purchasing new machine tools for their production, everything is examined very carefully at the Dresden site. “As a special-purpose machine manufacturer we produce every component just once, we do not have series production and do not produce for stock”, explains Joerg Stafie, Plant Manager at Glatt Systemtechnik GmbH in Dresden. “It is therefore particularly important for us that our machines enable us to fulfil every single order at the first go, in the desired quality and within the time specified. What matters to us is process reliability and speed. When we require new production machinery we have to invest millions, and they therefore have to live up to their promises.” Before we purchase a new machine we carry out extensive tests which are anything but trivial. The new machine has to prove its worth on a test workpiece – otherwise there is no approval for purchase.

“We needed a true tool specialist with relevant experience and knowledge of various tool manufacturers’ brands. This is how we discovered the Hoffmann Group. As a dealer, the Hoffmann Group has the advantage of in-depth knowledge of its own GARANT products and also of other manufacturers’ products, and they also have skilled application technicians who look after their customers on site. This practical knowledge is immediately noticeable when you talk to them.”

Mario Kühn, Foreman Machining at Glatt Systemtechnik

20 geometries on one test workpiece

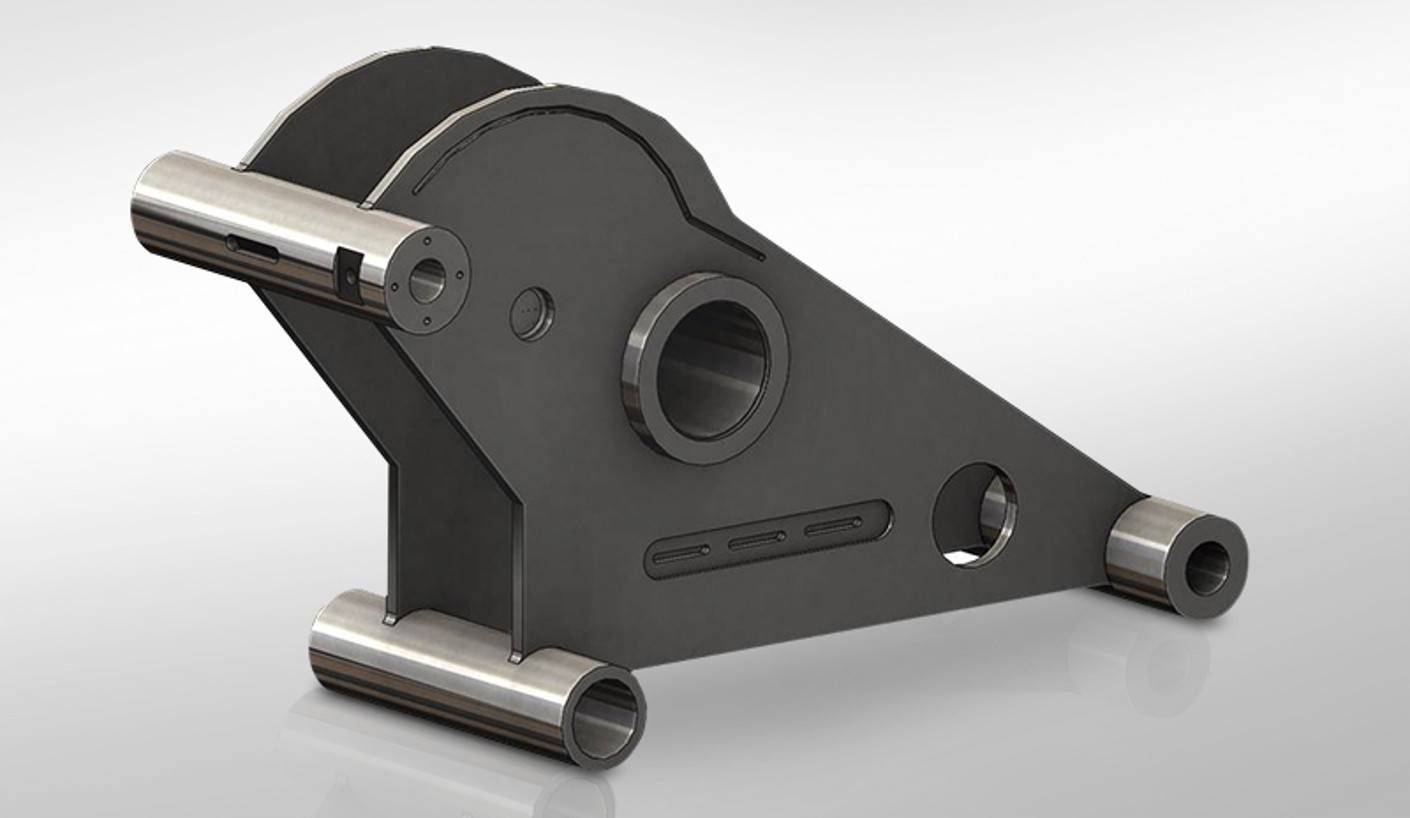

Glatt replaces two machine tools per year in order to keep their production equipment, consisting of about 30 machine tools, up-to-date. In 2016 it was decided to purchase, amongst other things, a new boring machine; in 2017 a new milling machine was to be purchased. Three machines each fulfilled the technical specifications required. The question that now arose was how successful would these machines be in a practical test, and would they be able to reliably fulfil the quality and time requirements. For these tests a stainless steel component was designed as a highly complex welding assembly featuring all the geometries to be processed in future.

“We wanted to identify the machines’ limits so that we could be sure we were spending our money wisely”, says Thomas Haubold, Head of Pre-Production at Glatt. “That’s why we put the geometries of 20 components, including special outer and inner contours, and bores of 0.2 millimetre diameter, onto the test workpieces. The only things missing at that point were the appropriate tools. Because the tools are of significant importance when you want to get the best out of the machine.”

Machining strategy with tool recommendation

With their service package “ToolConcept”, the Hoffmann Group offers a solution for complete processing of components, focusing on specific customer requirements. The Hoffmann Group adviser is thus not just focusing on the tools but on the complete processing operation – from planning through to post-processing. At the beginning of ToolConcept is the in-depth analysis and the definition of the technical task under the given conditions. Professional machining experts with experience in external sales develop the machining strategy for each step of the processing operation and thus in sum the complete machining process for the component. After that it is decided which machining tools and clamping processes are to be used. The result is a detailed machining concept with clamping solution, machining strategy, tool recommendations, technology and CAD data, and a commercial analysis. To ensure component quality the customer can request an additional recommendation regarding measurement strategy and measuring instruments.

90% reduction of cycle times, 70 % reduction of costs

At Glatt the Hoffmann Group ultimately found out that for part of the process a standard tool could be used instead of the special tool recommended by the manufacturer, by using additional finish boring. Mario Kühn is enthusiastic: “Due to the additional finish boring we are more flexible, and we have also increased process reliability.” Overall the total number of tools recommended by the Hoffmann Group for both machines amounts to approx. 60 pieces. 80% of these are from their own premium tool brand GARANT. “For machining tasks we have high-performance GARANT tools which, however, do not cover all specialised applications”, says Reinhard Beyer, Team Leader ToolConcept at the Hoffmann Group. “That’s the reason we are not focused solely on our own brands. It is exactly this flexibility that gives the Hoffmann Group a big advantage.

Incidentally, the TOS WHQ CNC boring machine and the Micron VCE 1000Pro made it to the top of the list of the most suitable machine tools. Today, Glatt produces some components in just two hours; in the past, producing them using conventional machining required three shifts. This equates to a reduction of cycle times of 90 % and a simultaneous reduction of production costs of 70%.

“We were convinced by the approach of the Hoffmann Group. Next we will purchase a new lathe and test it with ToolConcept – the effects will be even greater. For us the Hoffmann Group is not just a supplier, but a real system partner.”

Joerg Stadie, Plant Manager at Glatt Systemtechnik