Setup times cut thanks to the GARANT Xpent

Arnoldi Zerspanungstechnik GmbH, was founded in 2006. Today, the company has 15 employees and headquarters in Herzogenrath-Kohlscheid (Germany). This relatively young setup uses especially modern equipment. Its machinery consists of nine CNC machining centres with three and five axes for milling and turning, as well as the latest 3D CNC measuring technologies. The company’s strengths also include innovations in machining, prototype construction and component assembly, as well as advice on production queries, design and development. Highly qualified employees with many years of professional experience are committed to passing on their knowledge and expertise to those they train and provide a professional service. Arnoldi primarily works for customers within the packaging and grocery industries, including SIG Combibloc, Elopak and Teekanne.

“We can wholeheartedly recommend the GARANT Xpent. We’ve been working with it pretty much from day 1 and are extremely satisfied”

Rudolf Arnoldi, Managing Director at Arnoldi Zerspanungstechnik GmbH

Setup times cut by ten percent

Arnoldi Zerspanungstechnik GmbH has been using the GARANT Xpent 5-axis vice in its 5-axis simultaneous machining centre since the summer of 2017. This has enabled the company to reduce setup times by around ten percent. In particular, chrome-nickel steels and high-strength aluminium materials are machined simultaneously.

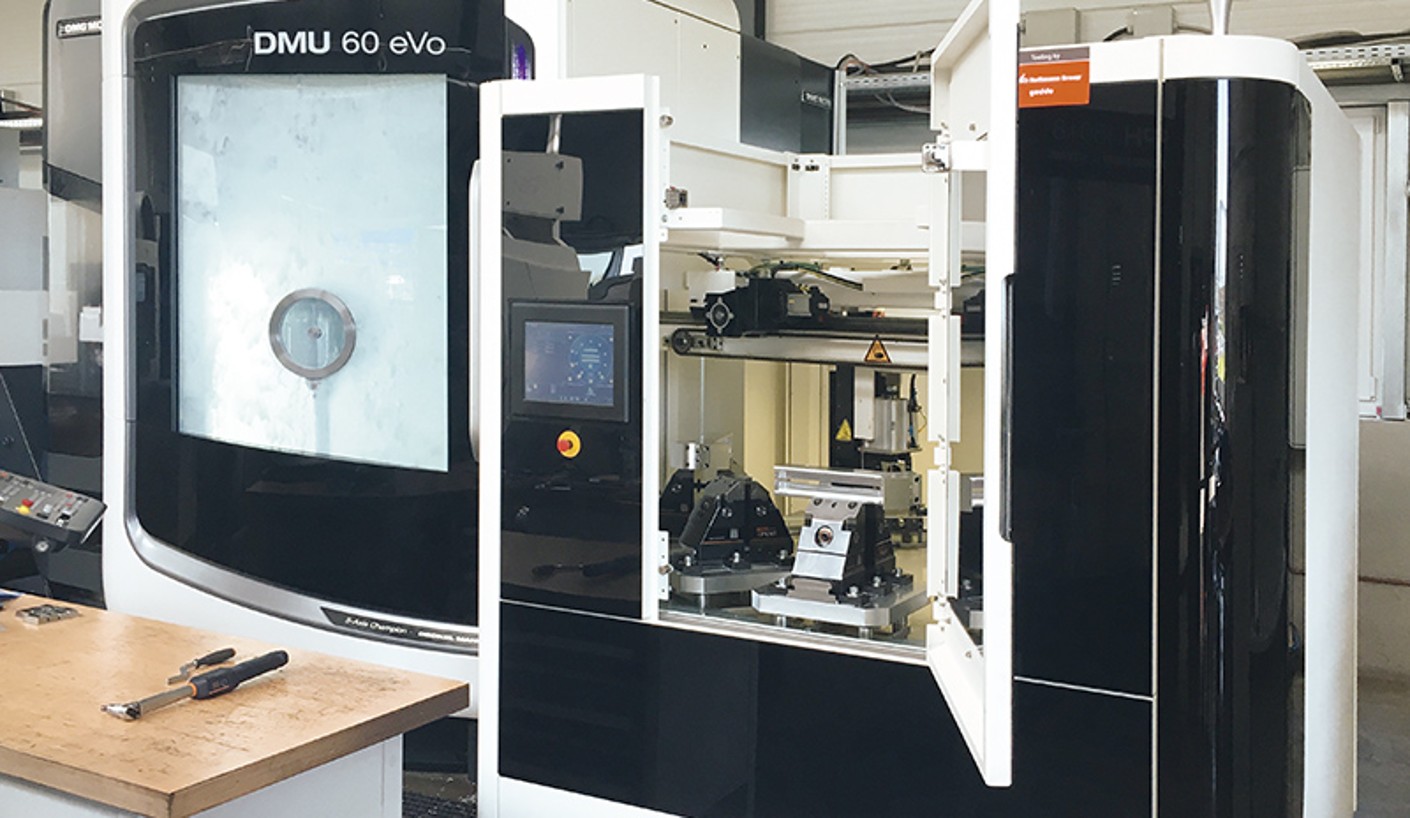

“In 2017, we procured the 5-axis simultaneous machining centre with 10x pallet changing system from DMG Mori. To enable full utilisation of this highly efficient machine, we needed the right clamping device,” reports Rudolf Arnoldi, managing director of Arnoldi Zerspanungstechnik GmbH. “I’ve been familiar with the Hoffmann Group for around 40 years now; the company has an impressive range of products and services. Through regular contact with the application technicians, we eventually became aware of GARANT Xpent 5-axis vice. In a comparison test, this vice beat the competition with its flexibility, clamping force, installed height and ease of use.”

The simultaneous machining centre at Arnoli has been productive with ten 5-axis vices since the summer of 2017. As the only clamping device for complete machining of components, the GARANT Xpent is fixed to the ten pallets and used on a daily basis. Another machine was equipped this way at the beginning of this year. The GARANT Xpent is primarily used in the simultaneous machining of chrome-nickel steels and high-strength aluminium materials. The clamping technology has a key role to play in this area, as the clamping strategy has a significant impact on how effective machining can be.

Simple to use, flexible and modular

Almost a year after purchasing, Rudolf Arnoldi has reached a positive conclusion: “With an investment as large as a 5-axis simultaneous machining centre with 10x pallet changing system, the setup and ancillary times must be as low as possible to achieve faster amortisation of the machine. The GARANT Xpent is precisely the right clamping system to achieve this, as we machine only small unit quantities and therefore need to change equipment over several times a day. The GARANT Xpent is very easy to use, flexible and versatile. It has enabled us to reduce setup time by around ten percent,” continues Arnoldi.

Following these positive experiences, Arnoldi is planning to purchase another 5-axis machining centre with pallet system and to equip it with the GARANT Xpent: says Arnoldi in conclusion.