Your partner during every step of additive manufacturing

The Hoffmann Group sees enormous potential in additive manufacturing. This is also what the company‘s own 3D printing Competence Center stands for, where we explore the growth opportunities for this innovative technology.

The automotive, aerospace and steel industries all rely on 3D printing. This innovative production process is an important issue for the Hoffmann Group as well. The Hoffmann Group thus opened its own 3D printing Competence Centre, which utilises the three major current technologies. We are working intensively to systematically analyse the opportunities provided by 3D printing.

We combine this core technology with our products and services. So that we can continue to provide you, our customer, with innovative products and services that are best in class.

Quality tools for additive manufacturing

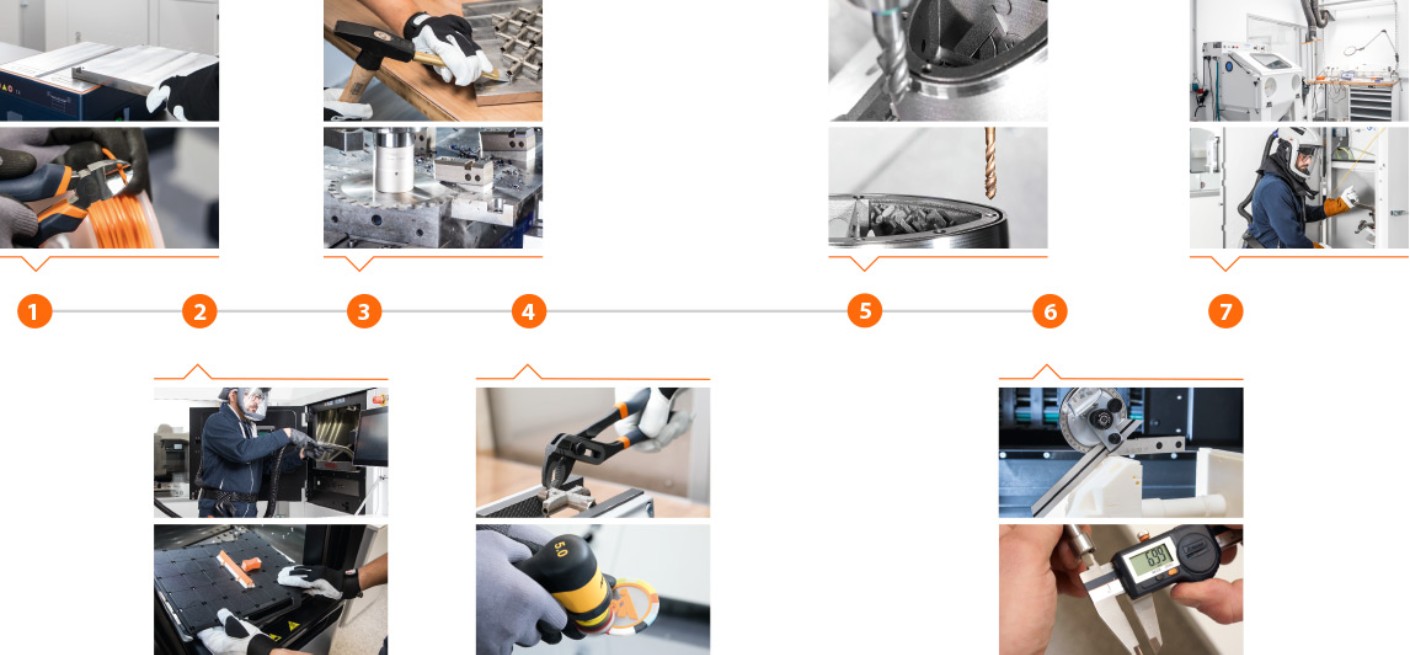

Pre-processing and post-processing in additive manufacturing are essential process components and thus crucial factors for the profitability of the technology. The Hoffmann Group accompanies you every step of the way.

1. Preparation/setting up

The machine is prepared for the printing process. For this, the relevant personal protective equipment (PPE) has to be worn and, additionally, various hand tools are required.

2. Building process incl. unpacking

During the production process the components are built up in the machine in layers. Following this, the parts or the platform are unpacked and taken out of the machine; here again, PPE is of vital importance.

3. Separation / release from the build platform

To separate / release the components from the build platform various processing methods and tools are used. These range from hammer and chisel, to spatula or knife, up to automated processes like a band saw or parting-off milling cutters.

Post-processing:

The proportion of post-processing can amount to 20-70% of the total process chain. Post-processing is subdivided into manual and mechanical post-processing.

4. Manual post-processing

The first step is to remove the supporting structure from the component in order to achieve the desired surface finish using the subsequent processing steps. These can involve various grinding tools and also polishing tools in order to achieve a high-gloss finish.

5. Mechanical post-processing

Machining comes into play in order to increase the degree of automation in post-processing. An allowance is included on the CAD model in order to finish free-form surfaces using innovative PPC milling. However, more conventional procedures like drilling, face milling, post-processing of bores etc. are also used.

6. Quality assurance

In order to ensure dimensional accuracy of the components, traditional measuring tools, like calipers and various gauges, are used. In additive manufacturing especially, a magnifier with scale is used, for example in order to check the layer thickness in the FDM process.

7. Maintenance / workstations & storage

Correct personal protective equipment is important during maintenance work on the machines, as highly flammable substances are being handled and as the focus is on protecting people. The Hoffmann Group can help you to fully meet this requirement with its "High End" range of PPE products.

Workstations and storage equipment are relevant in many process steps, for example for standardised and clean storage of the tools needed for post-processing and for setting up.

Customer opinion

Joachim Zettler, Managing Director of APWORKS GmbH: "Combining the advantages of metallic 3D printing with new materials opens up completely new possibilities in the production of components.” Nevertheless, all additive processes also require additional processing. Here, APWORKS relies on its long-time partner the Hoffmann Group for tools and equipment.

Joachim Zettler: “We value the Hoffmann Group as a loyal and reliable partner and we appreciate their pioneering spirit, accompanying us on our path toward innovative technology.”

To the customer story

To the customer story