Perfect profiles - Producing inner and outer profiles in seconds

GARANT profile spaces on the lathe

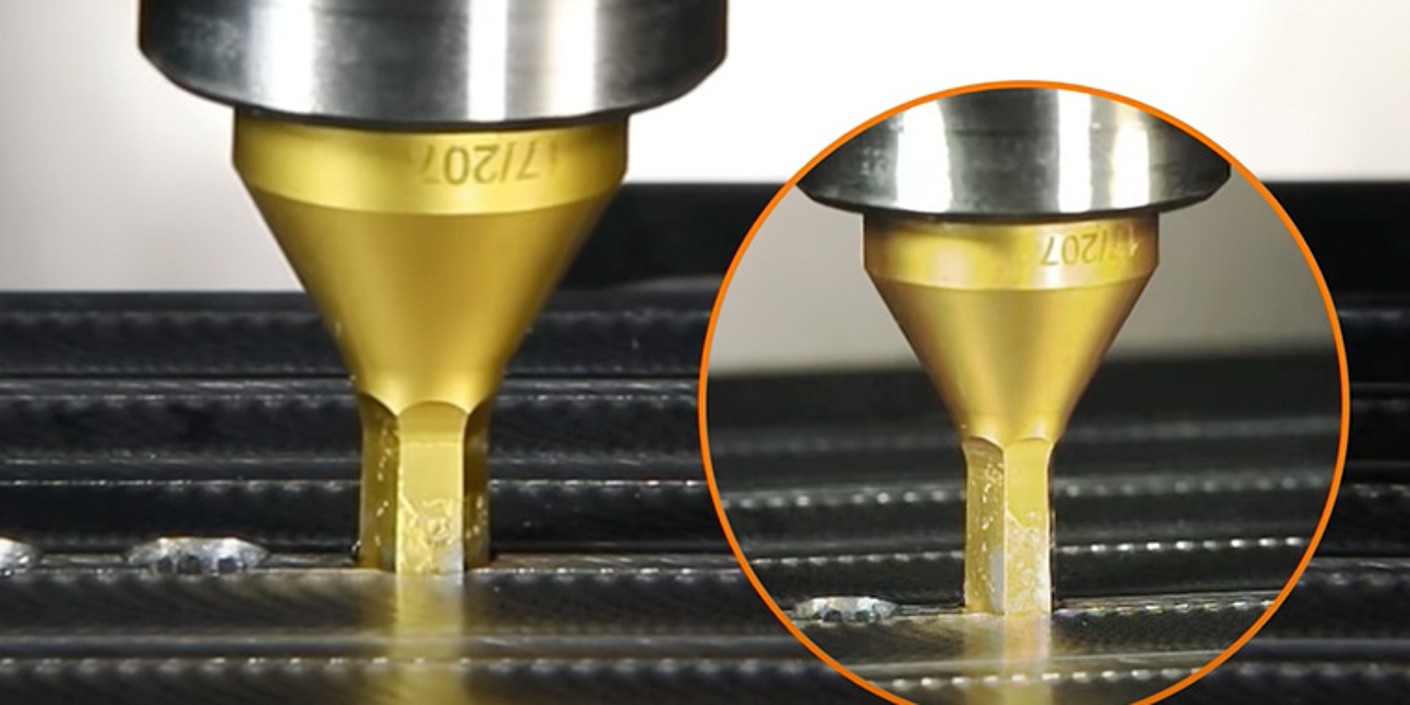

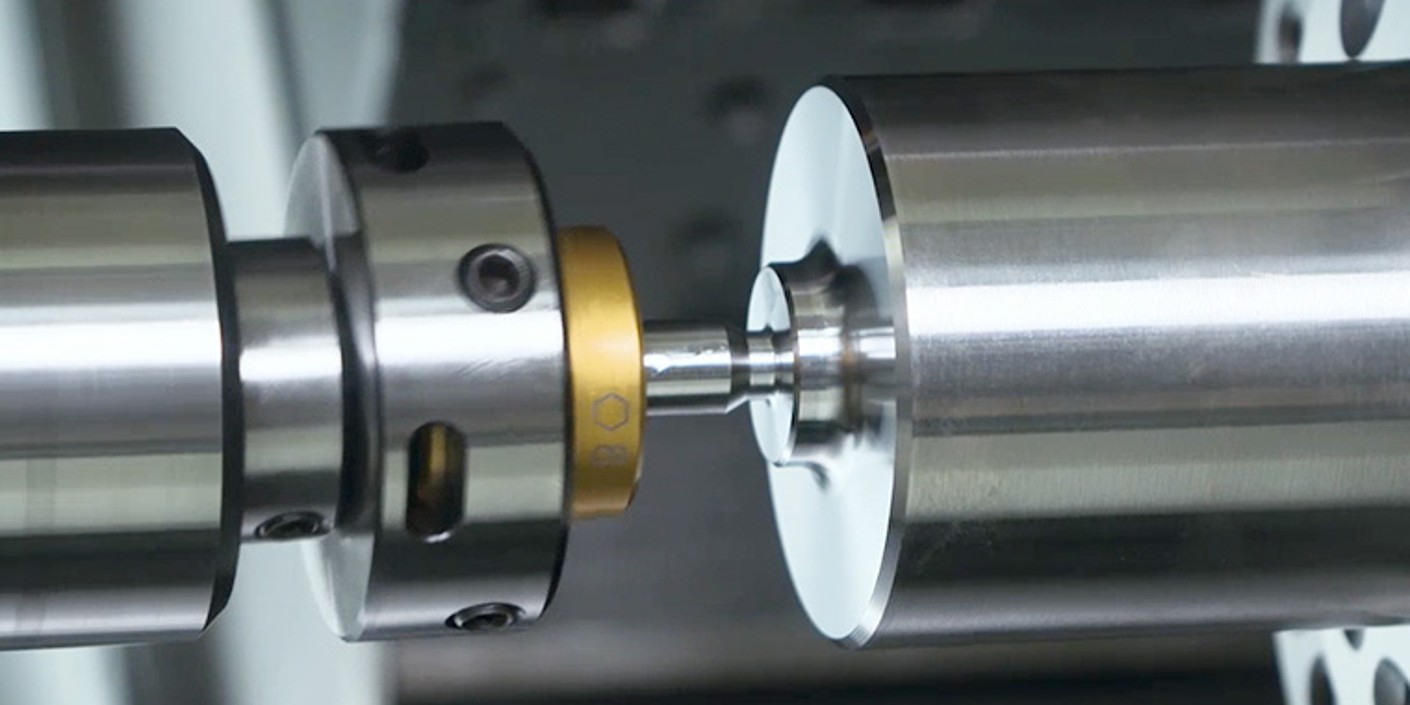

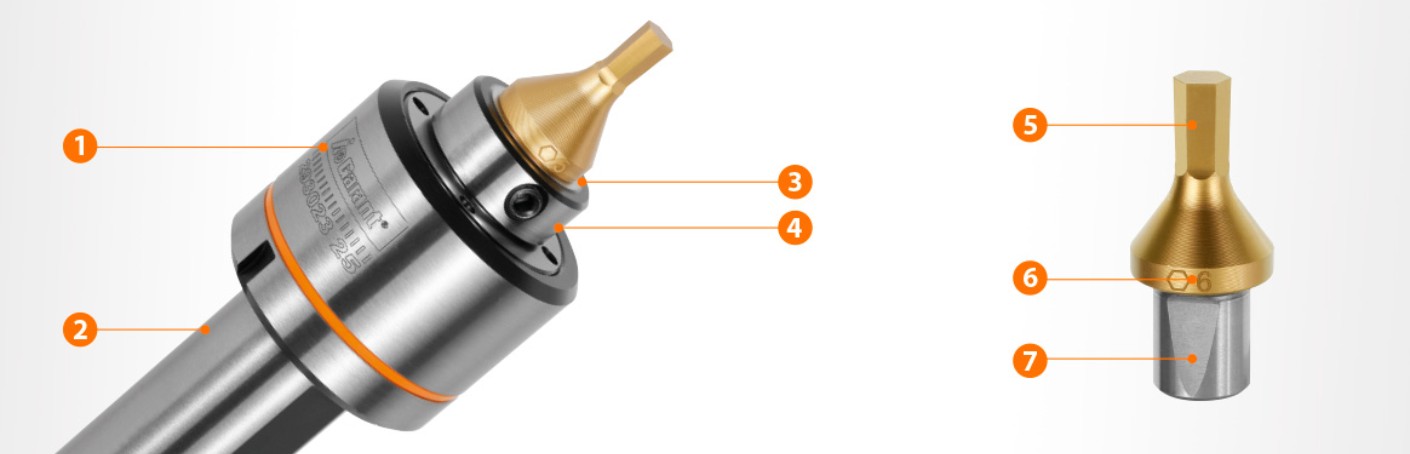

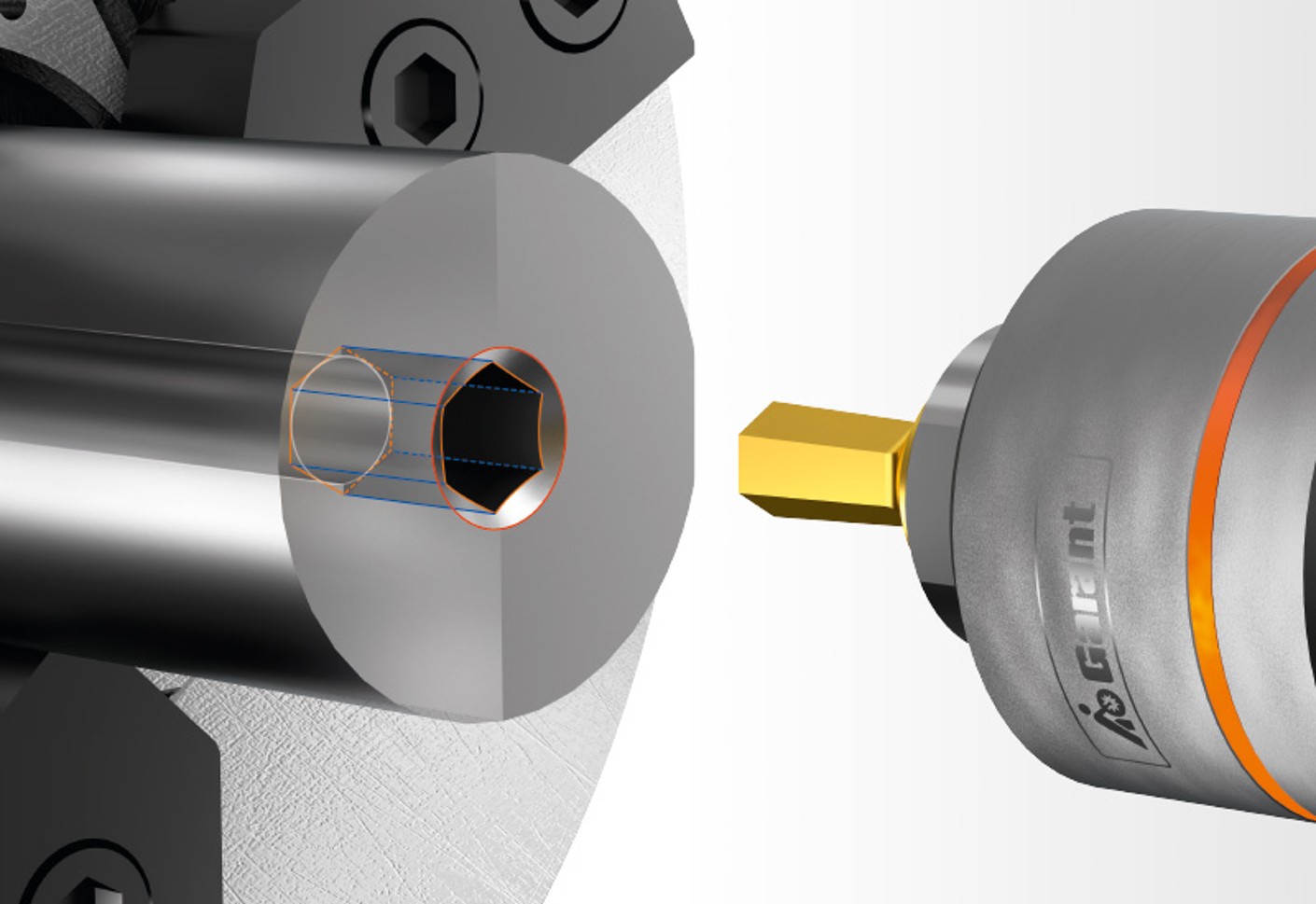

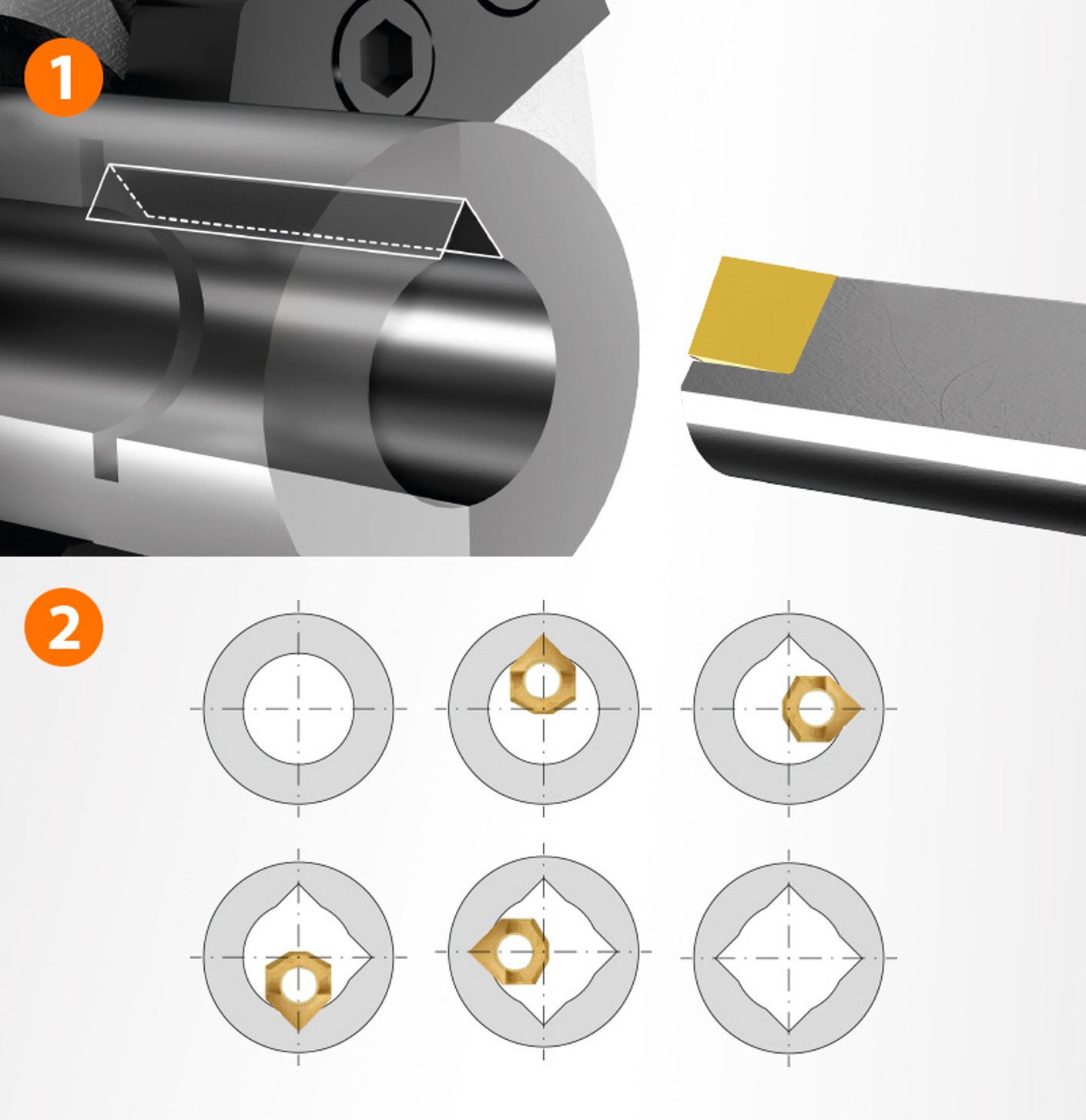

Profile broaching (also: tumbling) is a machining process. In profile broaching, a profile broaching insert is used to produce the desired profile (hexagonal, square or special profiles) in one operation by means of a concentric movement.

Always the right system for economical production of internal and external profiles:

With a complete range for broaching profiles on lathes and machining centres, GARANT offers highly productive, dimensionally accurate and process-reliable tools for complete machining.

Since our GARANT broaching process can be used on both lathes and machining centres, all changeover costs are eliminated. Furthermore, additional (cost-intensive) manufacturing processes such as wire-cut EDM (electrical discharge machining) can be dispensed with.

Your benefits at a glance:

- Rapid production of profiles in one work step

- Reduction of set-up costs

- No need to change machines

- No outsourcing needed

Innenprofile

- Prepare the hole

- Suggest a better translation

- To protect the cutting edge and reduce the processing time, pre-drill the workpiece with the largest possible drilling diameter.

- For a base hole, the following applies as a guide value for the drilling depth t: T = desired profile depth × factor 1.5

- A lowering of the hole facilitates the centering of the broaching insert.

- For larger hole diameters, the hole contour remains easily visible on the surfaces. This has no technical or qualitative restrictions on the functionality of the profile.

Click here for the profile broaching tools

Click here for the profile broaching tools

To the brochure GARANT profile broaching and slotting

To the brochure GARANT profile broaching and slotting