GARANT ZeroClamp – The versatile zero point clamping system

Precise and reliable clamping for tomorrow's complex tasks.

The growing complexity of production and the increasing diversity of components pose new challenges for the production process.

Garant ZeroClamp scores highly thanks to its simple design, high flexibility and unlimited range of applications. Thermal expansion is compensated by acting always in relation to the centre axis, so you need only one type of clamping stud. This offers you a great degree of freedom when arranging the clamping points, and also simplifies handling at all stages of production. GARANT ZeroClamp is the best way of setting up for production.

- Simple design

- High flexibility

- Unlimited range of applications

How the self-locking ZeroClamp clamping pot works

Garant ZeroClamp scores highly thanks to its simple design, high flexibility and unlimited range of applications. Thermal expansion is compensated by acting always in relation to the centre axis, so you need only one type of clamping stud. This offers you a great degree of freedom when arranging the clamping points, and also simplifies handling at all stages of production.

Advantages of the zero point clamping system

Increase of efficiency

Efficient and precise clamping with greater variability thanks to the innovative GARANT zero point clamping system.

Time saving

Up to 90% time saving due to lower set-up, changeover and non-productive times.

Increased productivity

Up to 70 % more productivity in your manufacturing process.

Cost savings

Saving the alternative costs of a new purchase due to optimised usage of the machines.

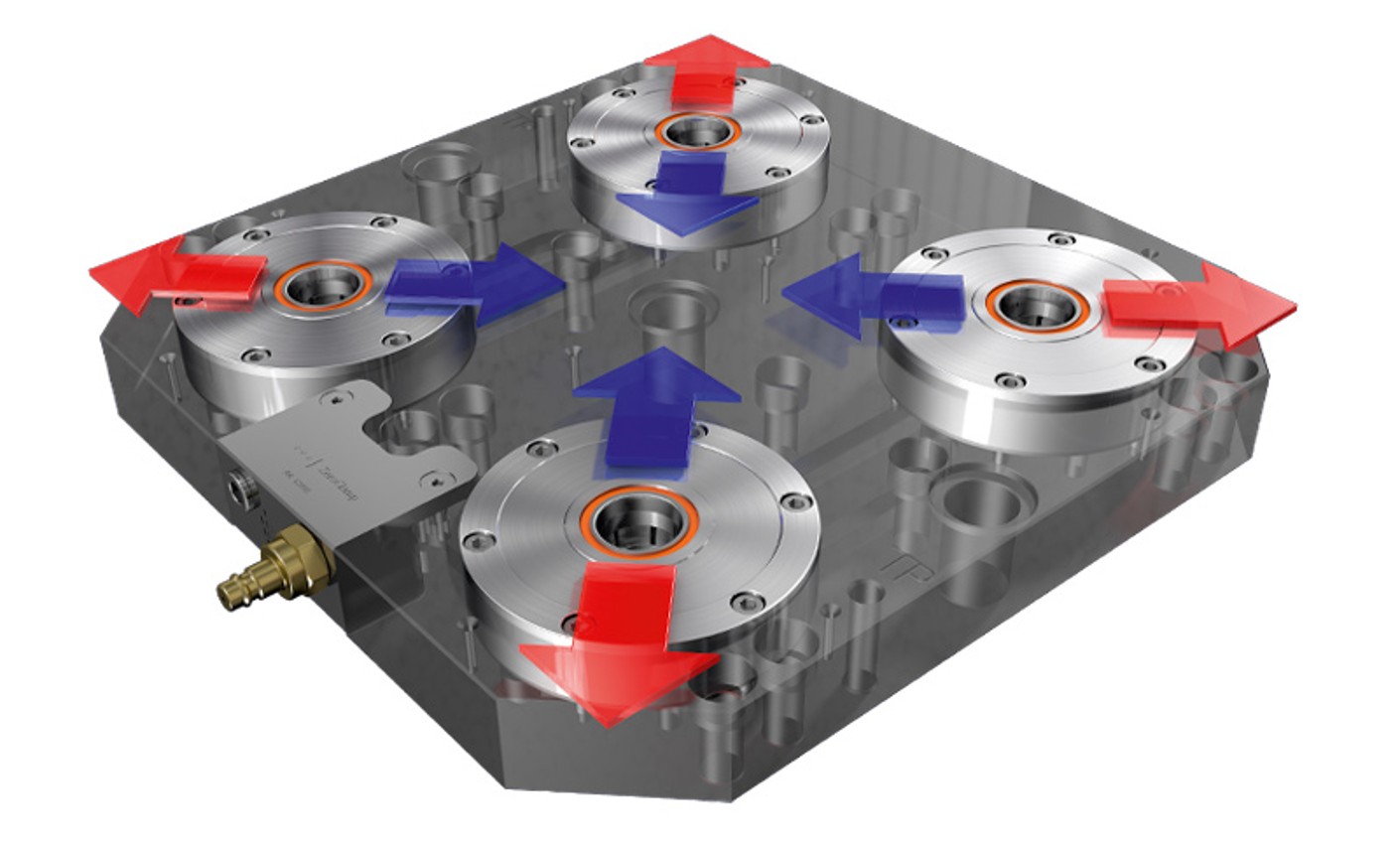

Thermal symmetry - always in relation to the centre

Conventional technologies use floating studs to compensate for thermal expansion – this produces particularly inaccurate results if workpieces are rotated around the central axis. Due to the central zero point, GARANT ZeroClamp provides absolute thermal symmetry at all times!

- The absolute zero point: Compensation for thermal expansion is always symmetrical about the central axis.

- Special zero-play clamping cones for low-vibration operation.

- No sword studs, no floating studs.

Simply brilliant

Only 5.5 bar compressed air is necessary to release the clamping studs – locking is by spring pressure.

- 25 kN clamping force with clamping pot ∅ 120 mm (40 kN at ∅ 138 mm), not self-locking.

- Low-maintenance, sealed system without hydraulic oil: no leakage, resistant to swarf.

- Process reliability thanks to easy application.

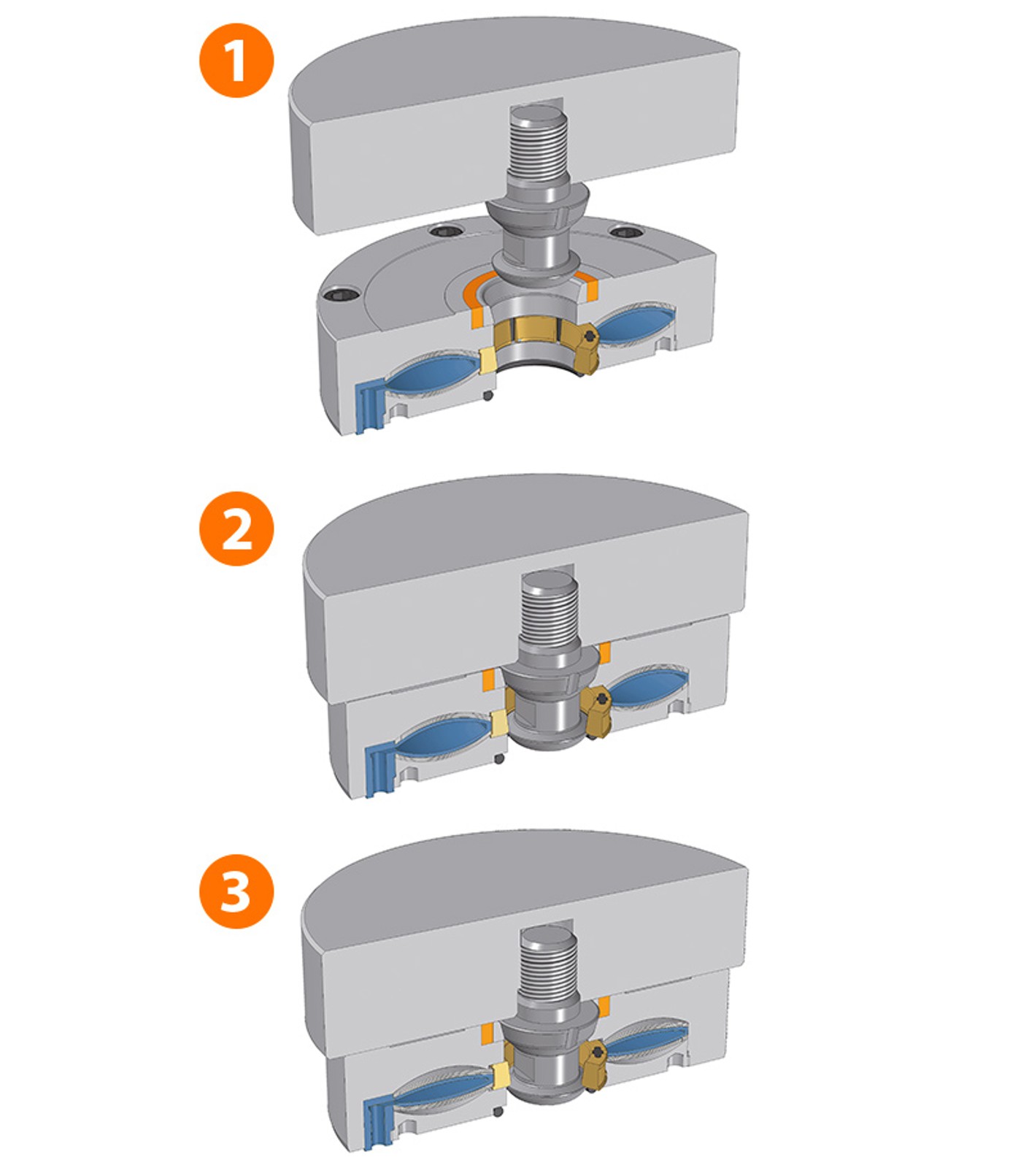

Operating principle in cross-section:

- The pallet is simply placed on the open GARANT ZeroClamp clamping pot. Therefore there is no risk of jamming.

- The spring elements keep the locking unit (clamping wedges) open due to the air pressure (5.5 bar) in the air hose.

- When the pressure in the air hose is released GARANT ZeroClamp positions the workpiece on the flat face with a clamping force of 25 kN (∅ 120 mm) and 2.5 μm repetition accuracy.

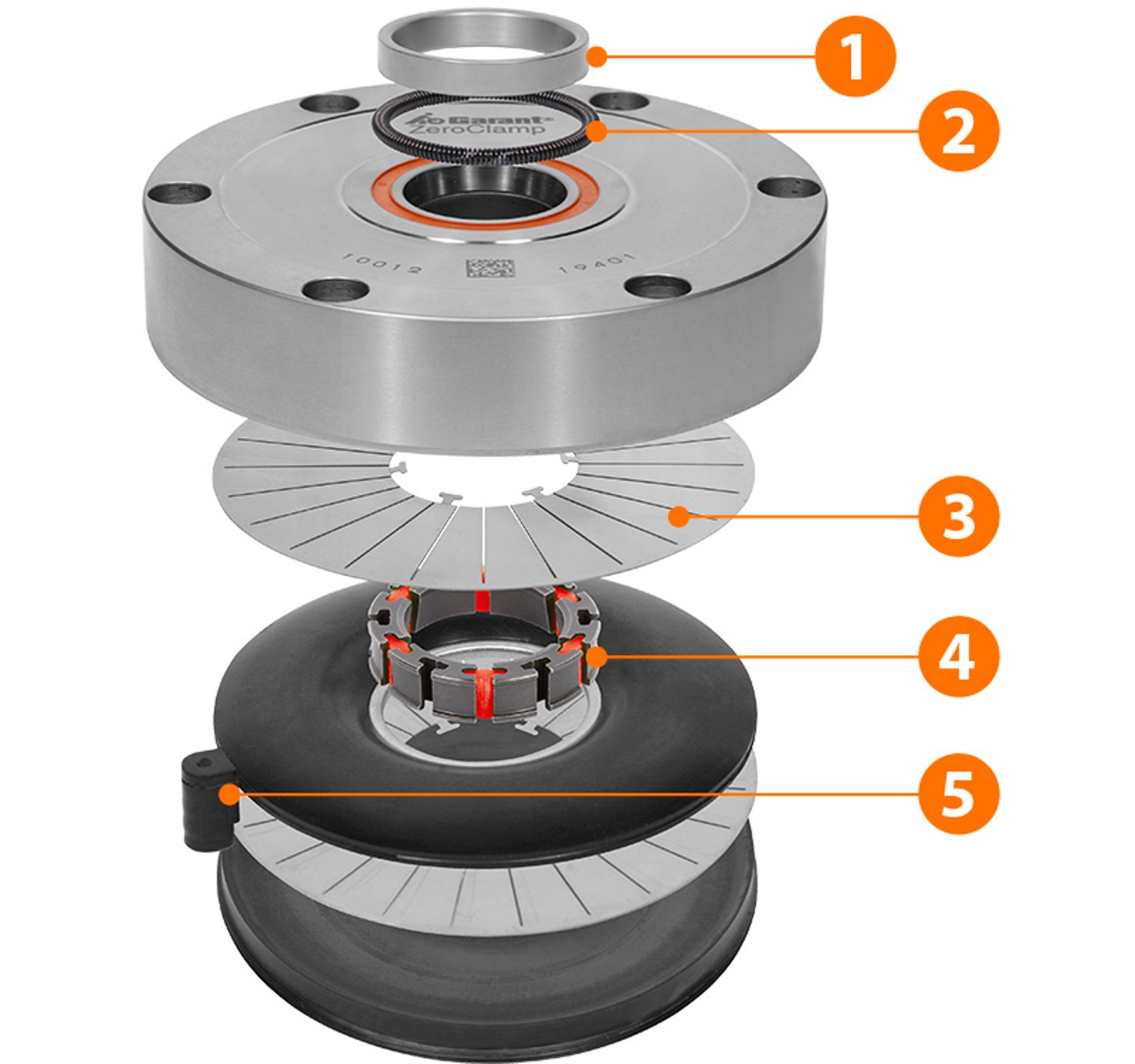

Optimised design

Only 8 parts for reliable clamping force.

- Centric clamping, free of backlash within the hardened steel taper

- Radial spring supported by Viton, high resistance against cooling lubricants

- Non-wearing technology, an air hose and clamping plates provide the required clamping force

- Locking unit

- Air connection for release

Our customers are impressed by GARANT ZeroClamp

Get in touch with us!

Do you still have questions, would you like personalised advice for your clamping challenge or would you like to receive a quote directly? Our trained advisors will be happy to help you! We take a very close look at your task, including the size of your components, the number of vises, the throat dimensions, etc., and find the right clamping solution for you.

Because the clamping device should adapt to you, not the other way round.

To the customer story

To the customer story