GARANT Master eco and GARANT eco: efficient clamp tool holders and new VDI tool holders

Efficient cooling technology for turning and grooving

GARANT „efficient cooling“ – the original: Works where it's needed!

With GARANT eco, the "efficient cooling" technology, we have created an innovative solution for the optimum cooling of machining processes. In the case of materials with low thermal conductivity the heat created during machining is not or not sufficiently dissipated via the swarf. The high temperatures lead to a decrease of the tool's life and to a drastic decrease of tool quality. Cooling of the cutting edge can reduce the development of heat, especially in materials with low thermal conductivity - this will lead to a marked improvement of the machining process.

The GARANT Master eco is the new generation of proven eco tools with additional flank face cooling and optional coolant transfer.

The new generation: GARANT Master eco

Based on our experience with our GARANT eco system, we were able to further develop the eco system. Our Master eco family was born. Here we have consistently further developed the technology – benefit from it.

These features are convincing on the whole:

1. eco – efficient cooling

Highly efficient cooling of the cutting edge.

2. Additional flank face cooling

Reduction of the thermal load.

Optimised chip clearance.

3. Optional coolant transfer

Alternative coolant feed via hose connection.

GARANT Master eco

Positioning within the scale ensures precise coolant transfer.

The new GARANT Master eco VDI toolholder family, form B and C

Innovative coolant adjustment

3 different coolant supply variants via coolant switch using adjusting screw:

Internal: eco cooling by the screw-on/lever lock/clamping toolholder.

External: cooling via ball spray nozzle.

Mix: internal + external.

Optimised accessibility

The screw-on/lever lock/clamping toolholder can be changed directly on the turret in the machine using the front mounting concept.

Very easy to use

The screw-on/lever lock/clamping toolholder is fixed to the GARANT Master eco VDI toolholder by means of only one fastening screw.

Discover now: HOLEX Pro eco Clamp toolholder

Precise and simple cooling at a clever price-value ratio! The comparison to the GARANT Master eco:

The tried and tested: GARANT eco

4 good reasons for choosing GARANT eco

Effective: Increase in productivity

With conventional applications, increases in productivity are limited so as not to immediately damage the cutter and coating. With GARANT eco, the heat working area is reduced so the indexable insert is exposed to less heat and higher cutting speeds are possible. This results in an increase in productivity.

Reliable: Higher process reliability

With conventional applications, the cutter is not sufficiently cooled or not cooled at all, particularly with deep grooving. This causes heat to build up. Sudden rinsing with the cooling lubricant after machining can therefore cause damage to the cutter. With GARANT eco, the temperature remains constant throughout the work process and therefore does not cause any thermal shock loads. This, in turn, results in higher process reliability.

Precise: Better surfaces

With conventional applications, there is no continual cooling lubrication effect and swarf can jam in the grooving area. With GARANT eco, the targeted cooling in the cutting area immediately ensures chip removal and reduces friction in the cutting area. The optimum chip evacuation and the use of the correct cooling lubricant ensure an improved surface.

Durable: Optimised tool life

Heat causes wear and this, in turn, results in the indexable insert needing to be replaced more often, which means higher costs. With GARANT eco, the wear on the insert is greatly reduced during processes that require cooling. As a result, the service life of the indexable insert increases and tool life is optimised.

GARANT eco – system variety

GARANT eco is the original and, right from the start, offers system variety, a comprehensive range of innovations and know-how at the highest level. With the right GARANT tool you can influence machining temperature and increase productivity. Here are a few examples:

GARANT eco practical test

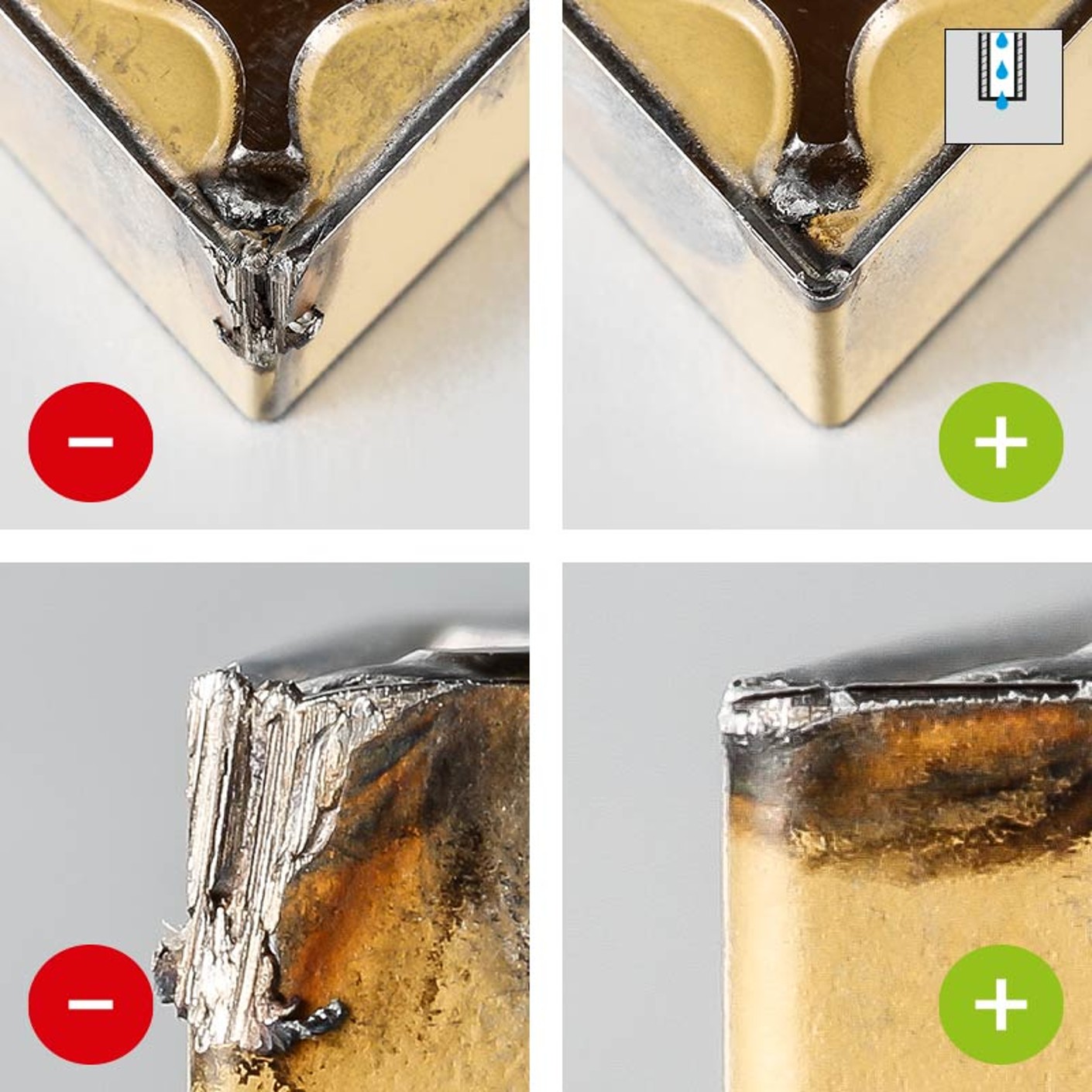

When comparing two inserts (identical processing of an unmachined part), one of which was used without GARANT eco cooling (left) and one with (right), marked differences are instantly visible.

The insert on the left which was used without cooling shows high crater wear. Also easily visible is the ductile deformation - the deformation of the cutting edge due to high thermal overload and high cutting forces.

The right insert was cooled with GARANT eco technology during machining and therefore shows an even width of the wear mark.

The use of precision nozzles for cooling effectively and efficiently reduces the thermal loading, since the coolant stream is optimally directed between the chip and the cutting edge. This results in higher productivity, longer tool life and higher process reliability.

GARANT eco cooling technology

GARANT eco stands for „efficient cooling“ and offers you optimum cooling during your machining processes. The temperature on the major and minor cutting edge is reduced significantly, making it possible to achieve a marked increase of cutting speed compared to conventional systems.

In our application video we describe the system and the structure of this innovation. We have summarised all the important facts about the various application areas such as turning, grooving and parting off.

View all GARANT eco tools in the eShop

All GARANT eco and GARANT Master eco products can be found in our eShop.

To the product

To the product